Data-driven decision-making is unlocking major dollar savings for shipping owners and operators. It is no longer just about increasing the fidelity in a vessel’s speed and consumption profile. Access to high frequency data has allowed Nautilus Labs to help our clients unlock insights that are driving optimized operations. We’ve discussed our Dynamic Speed Optimization (DSO) and how our machine learning techniques are informing our clients’ RPM instruction to the crew. As our clients begin to see the value that HFD has for their business and understanding of their vessels, they are increasingly relying on Nautilus Platform to determine how to operate their vessels in order to maximize their ROI. Determining a ship’s optimal trim, dynamically over the course of a voyage, is another such example of an optimization derived by our software.

Trim Optimization

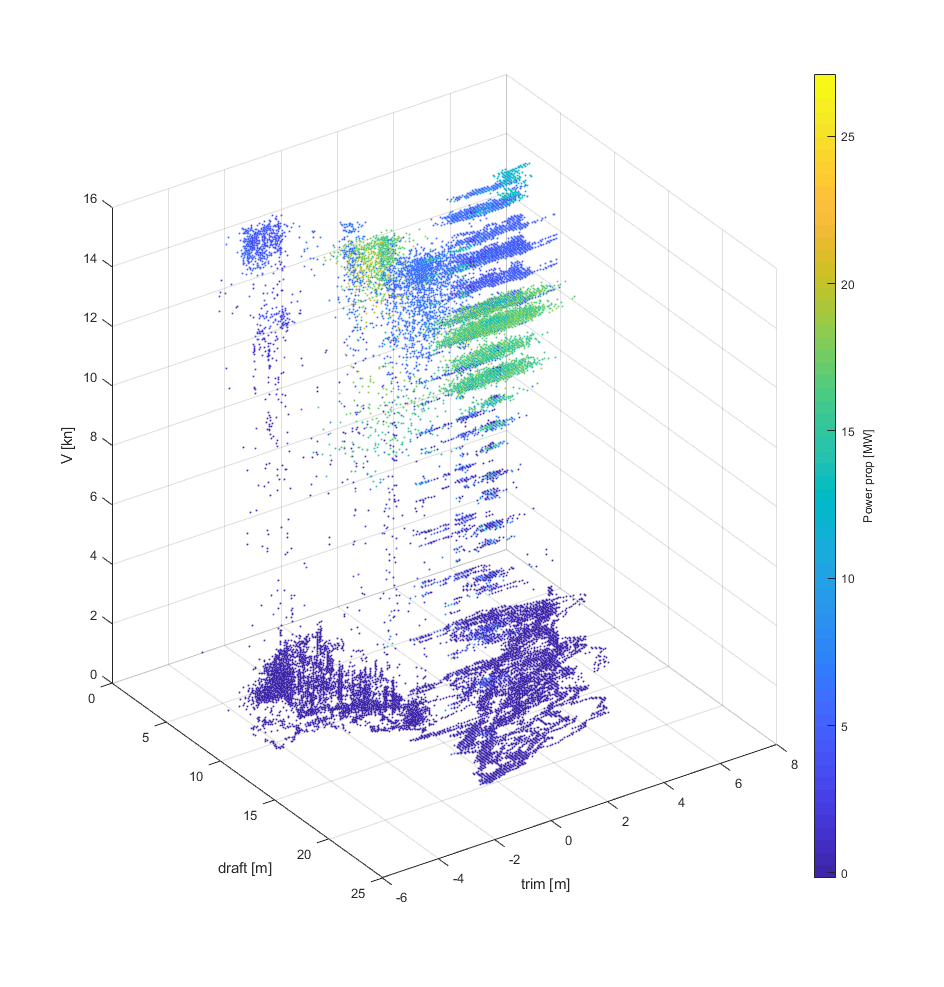

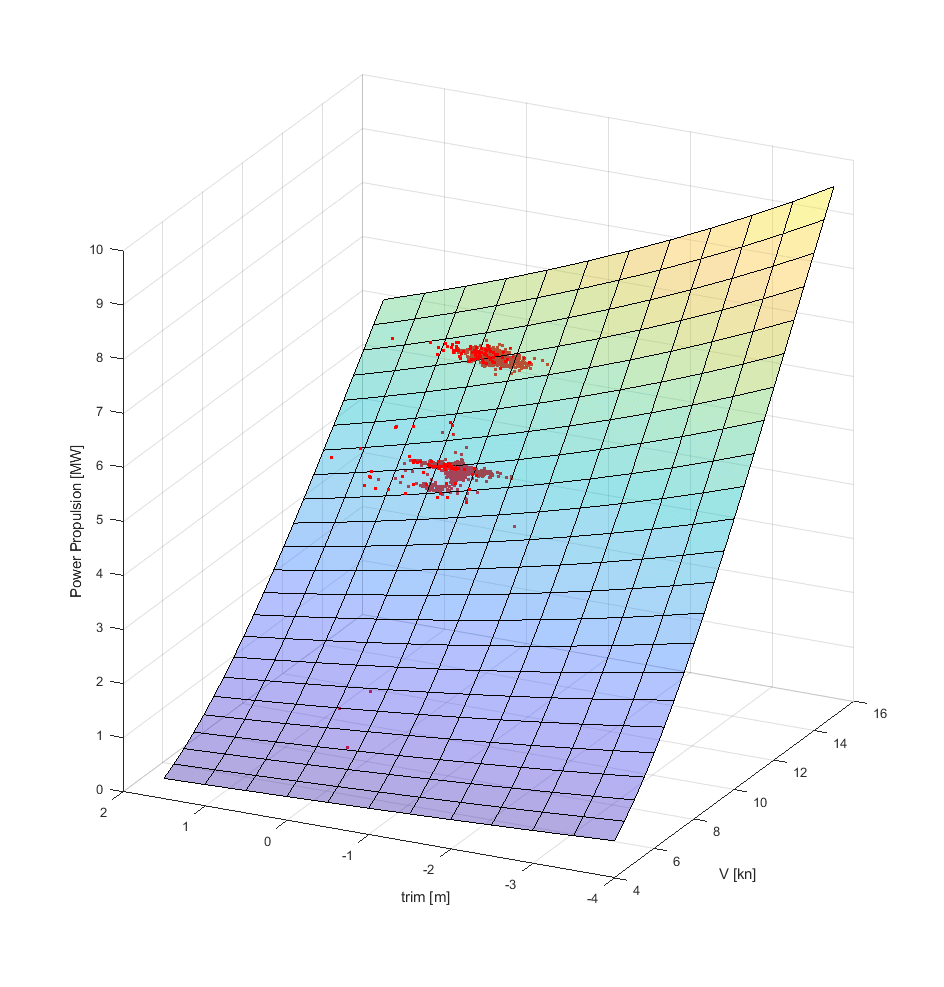

A vessel’s trim refers to its floating position in length, which can impact the water resistance it experiences along a voyage and therefore the amount of energy it needs to consume to progress forward. Trim optimization refers to identifying the exact trim the vessel needs to adjust to in order to minimize the vessel’s propulsive power demand under given speed, draft, and weather conditions. When tackling a challenge such as trim optimization, it is important to recognize that the nature of a vessel sailing in narrow ranges of operation leads to clustered data that needs to be properly deciphered, as shown in Figure 1.

The color of each pixel in Figure 1 correlates to an engine power output. In a sense, identifying the optimal trim requires making inferences on the color of each pixel in the empty space of Figure 1 using data on pixels provided. How does one go about defining the relationship between trim, power, fuel consumptions, speed, draft and weather, given such clustered data points?

Machine Learning Approach

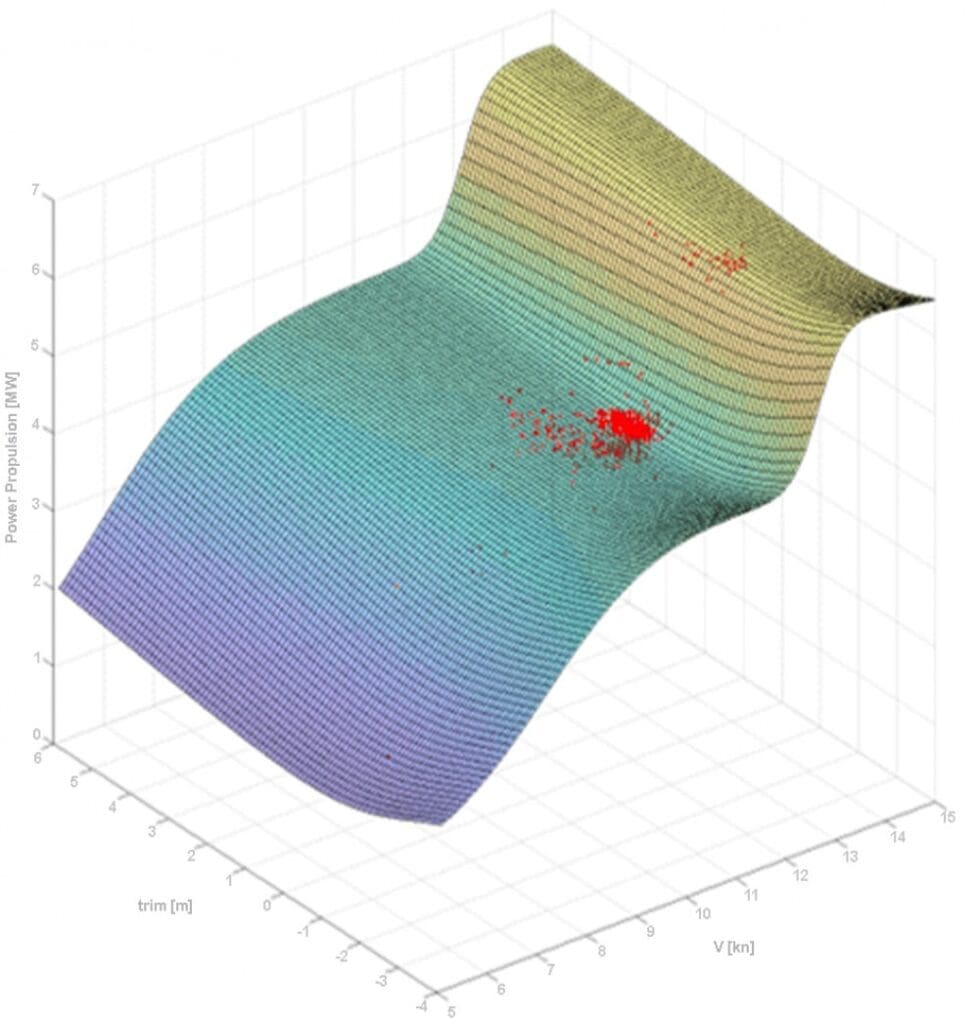

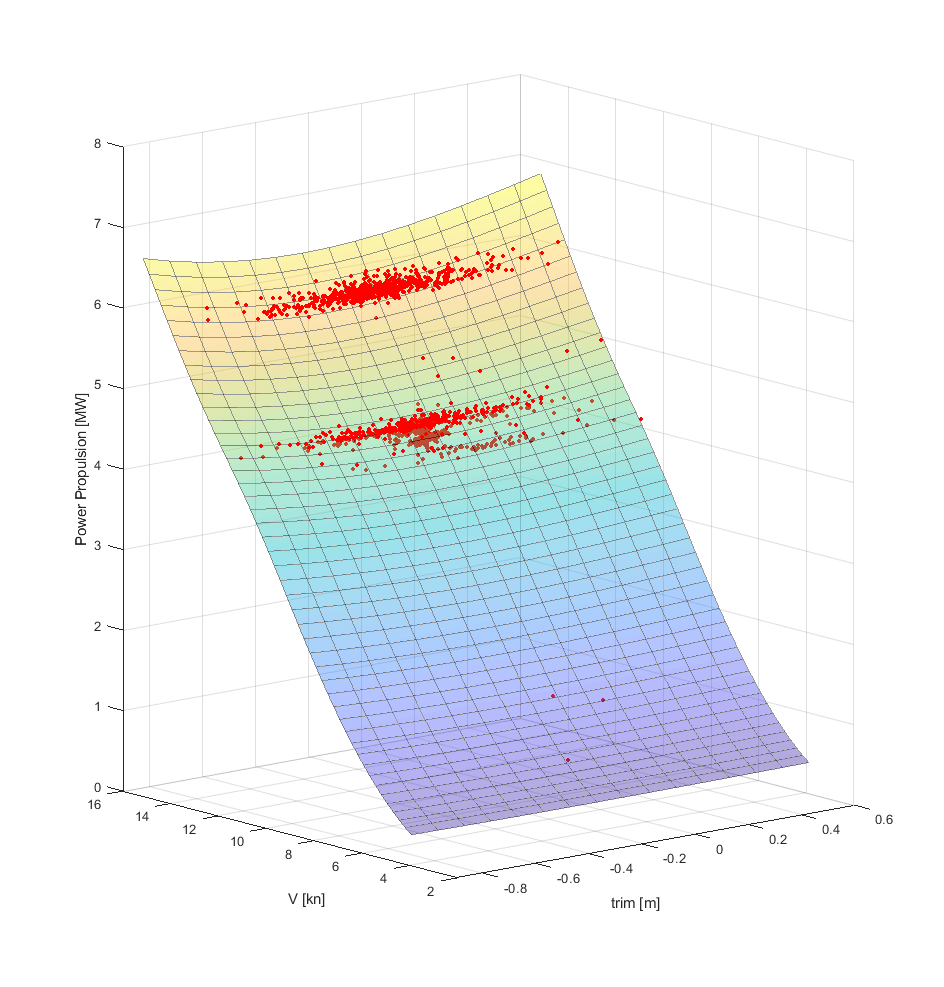

Statistical machine learning approaches have become some of the go-to methodologies used to tackle this question. A fundamental advantage of machine learning is that it doesn’t require any underlying assumption about the intrinsic relationship between data points in order to produce a relationship between them. With sample data from a vessel on our platform, we ran a machine learning methodology for given draft and weather conditions, and identified the below relationship seen in Figure 2.

Without any scientific context that governs the physical relationship of the variables in question, the machine learning approach will result in a model with low error metrics but one that overfits for the available data. Thus, while it will appear to be accurately portraying the relationship between trim, power, etc. it will be nominally overfitting to the available data, not taking into account the principles of naval architecture that govern the closed-form relationship among variables such as trim, power and speed for given draft and weather conditions.

Naval Architecture Approach

A tempting alternative would be solely relying on principles of naval architecture to develop a closed-form expression that captures the essence of the problem. This approach, for given draft and weather conditions, would lead to the solution pictured in Figure 3.

This solution, while scientifically sound, would fail to capture the intricacies and particularities of the specific vessel on its unique voyage under unique conditions. This solution would lead an ship operator to believe that operating with a marginally positive trim, or going by the bow, is always a good approach, regardless of the ship; neglecting the common-sense rule of thumb that ships are designed to sail with even keel. Thus, it is expected that, under design conditions, the optimum trim shouldn’t be far off the even keel trim.

Nautilus Approach

Our solution at Nautilus Labs combines the best of both approaches. We use principles of naval architecture to build a scaffolding for the model to preserve the intrinsic relationships between the fundamental parameters of the ship. We then overlay this scaffolding with statistical machine learning to fine tune the model to the data on hand, thus accounting for the particularities of the ship.

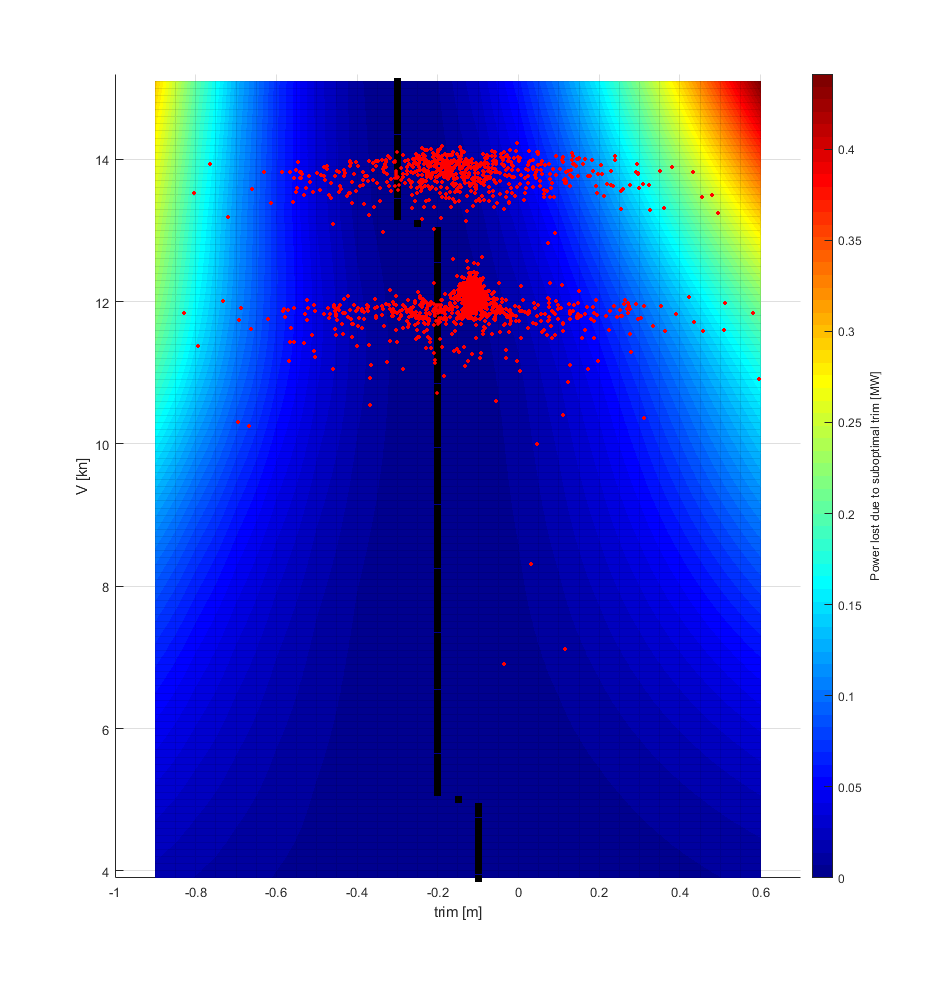

The surface of our solution in Figure 4 corresponds to a specific set of draft and weather conditions. For visualization purposes, the raw data points correspond to an interval centered in the target conditions. For any given speed along the surface of Figure 4 there is a trim that minimizes the engine’s power demand. Using a combined machine learning and naval architecture approach, Nautilus identifies the optimal trim that minimizes the engine’s power demand and, ultimately, fuel consumption. Graphically, visualizing the optimal trim shows how power increases as the the vessel’s trim deviates from optimal. The power lost associated with the deviation from optimal trim is reflected in Figure 5.

Nautilus has identified an accurate optimal trim for our clients that equates to over 5% in fuel savings along each vessel’s respective voyage. Now more than ever, it is becoming important to look under the hood of your data collection and analysis processes and embrace the use of high frequency data to conduct smart optimizations using the latest technologies and methodologies available.

At Nautilus Labs, we can help you do that.Our solution at Nautilus Labs helps our clients to optimize for variables such as trim in order to reduce the demand of energy for propulsion during sailing. We use our proprietary machine learning models combined with our naval architecture expertise to provide accurate and real-time insights that help our clients make data-driven decisions to enhance the performance and efficiency of their fleet, and to maximize ROI.