Reduce LNG Consumption while Meeting ETA and Terminal Requirements

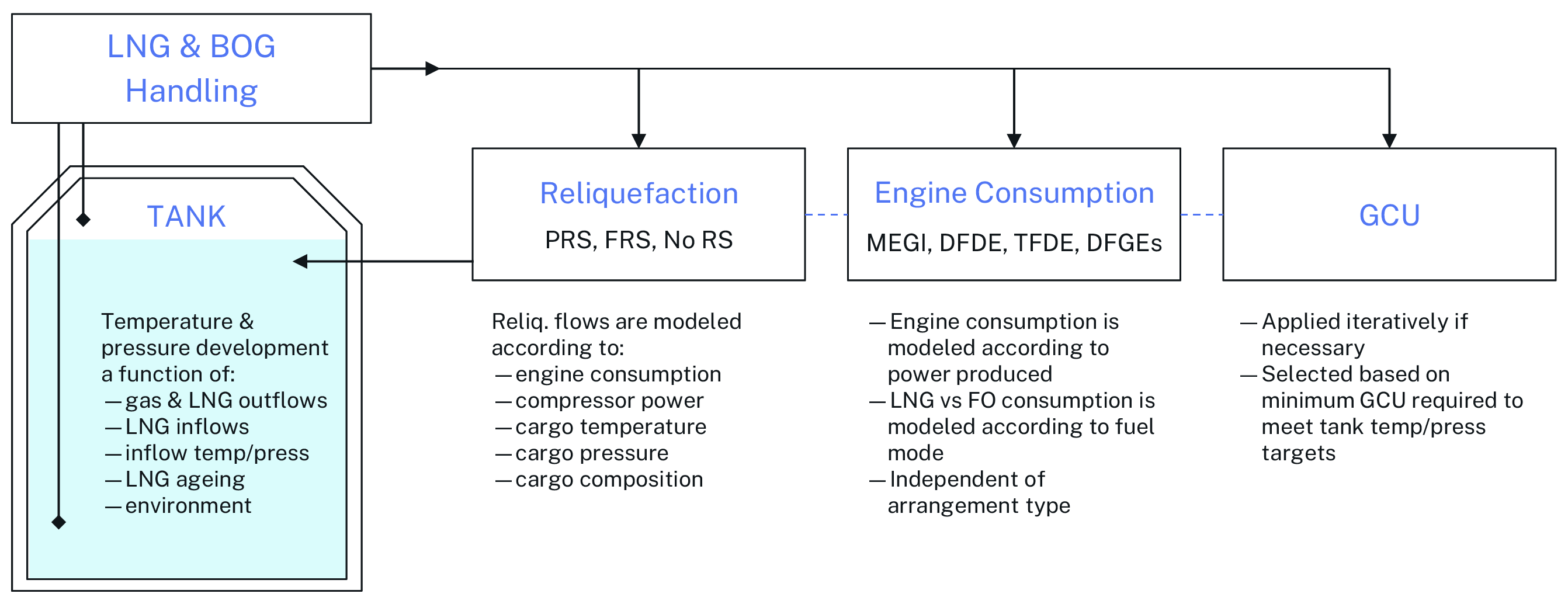

The complexity of LNGC systems and cargo aging makes predicting the effects of consumption and reliquefaction on cargo condition very difficult to estimate accurately because of the relationships between these systems’ performance, the environment, and the cargo condition. This hampers the ability to accurately measure and track LNGC performance over voyages.

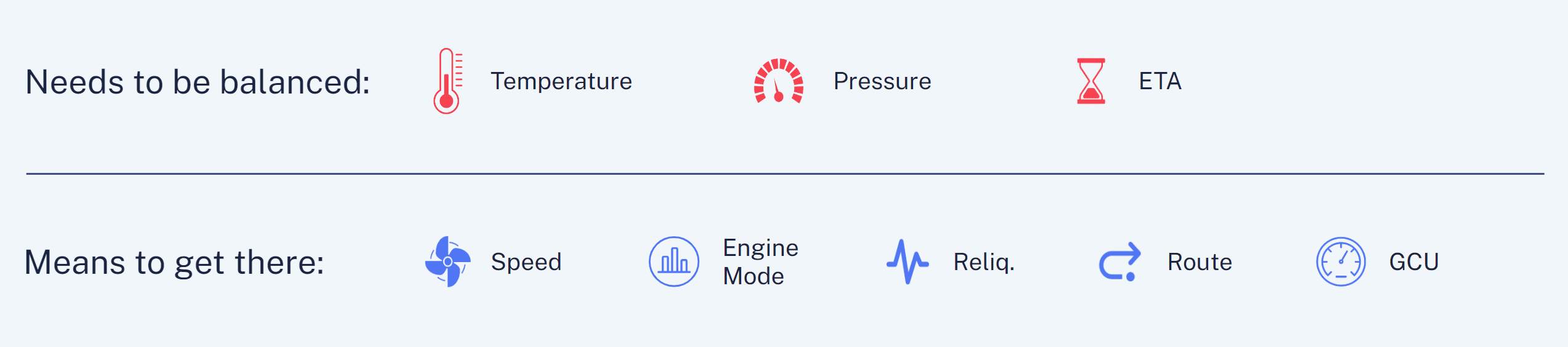

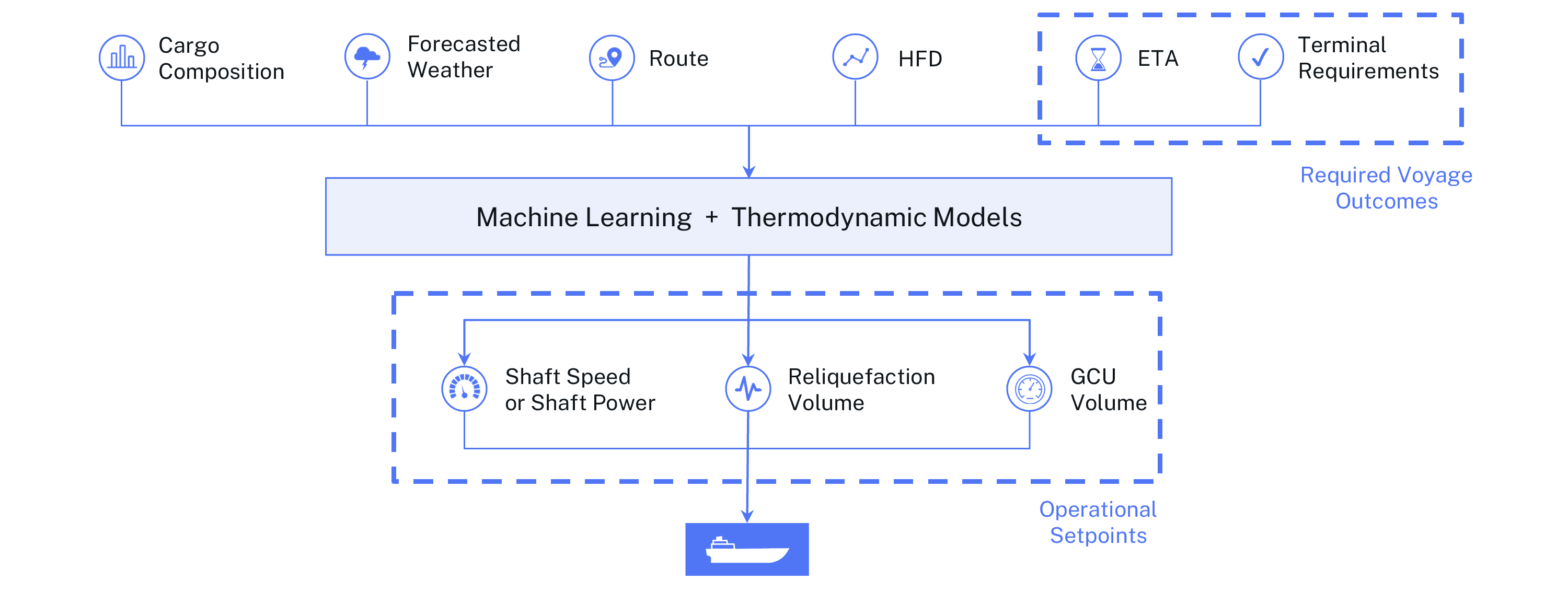

Additionally, Operations and Technical teams must balance multiple levers (like shaft speed, reliquefaction rate, fuel mode, GCU, etc) to manage the challenges of boil-off gas when planning and executing voyages. However, doing so while minimzing LNG consumption can be complex, especially when aiming for specific ETAs or terminal requirements. Most performance estimation methods and tools used today for LNGC performance monitoring and voyage planning cannot accurately predict the impact of operational changes on voyage performance in different scenarios to understand the best possible operational setpoints.

These challenges are significant – suboptimal management of boil-off gas can result in tens of thousands of dollars worth of lost LNG cargo per voyage.

Our Boil-off Gas management solutions allow users to simulate LNGC voyages, modeling changes in cargo composition, temperature, and pressure over the course of a voyage with a high level of accuracy, contextualized by predicted speed & consumption, reliquefaction, and the impact of forecasted weather & sloshing. These simulations are leveraged to optimize voyages by surfacing optimal operational setpoints, and provide decision making support to users with in-depth simulated voyage outcomes.

BOG Solutions

Boil Off Gas Simulator

Empowers Predictive Insight

BOG Simulation facilitates data-driven decision making around key voyage planning, assessment, and approval decisions pre and mid voyage. Simulations of expected vessel performance and voyage outcomes will arm both Charterer and Owner Operations teams with the data they need to make operational decisions that increase voyage efficiency, at the time they are making those decisions.

Remove the guesswork from voyage planning and decision making to maximize voyage economics by simulating any operational setpoints and/or terminal requirements. Simulation results present detailed reports of voyage outcomes, including: consumption breakdowns, cargo temperature, pressure and composition development forecasts, reliquefaction performance predictions, and SOG / ETA predictions.

Boil Off Gas Optimizer

Prescribes Best Operation

Understanding the best operational strategy in the face of changing weather, dynamic cargo, and midvoyage adjustments is a complex challenge while balancing voyage requirements and optimal performance. BOG Optimization offers recommendations to vessels and operations teams to minimize LNG consumption over the course of the voyage, updated daily to account for changing conditions.

Based on siumulation of vessel performance over the remaining voyage, BOG optimziation perscribes operational setpoints (shaft speed, reliquefaction or subcooling rate, GCU consumption) that optimize for minimum LNG consumption while ensuring adherence to voyage outcome requirements, enabling a better understanding of how to best undergo a voyage in changing conditions.

BOG Modeling

Hyper-accurate Predictive Models That Enable the Most Informed Decisions

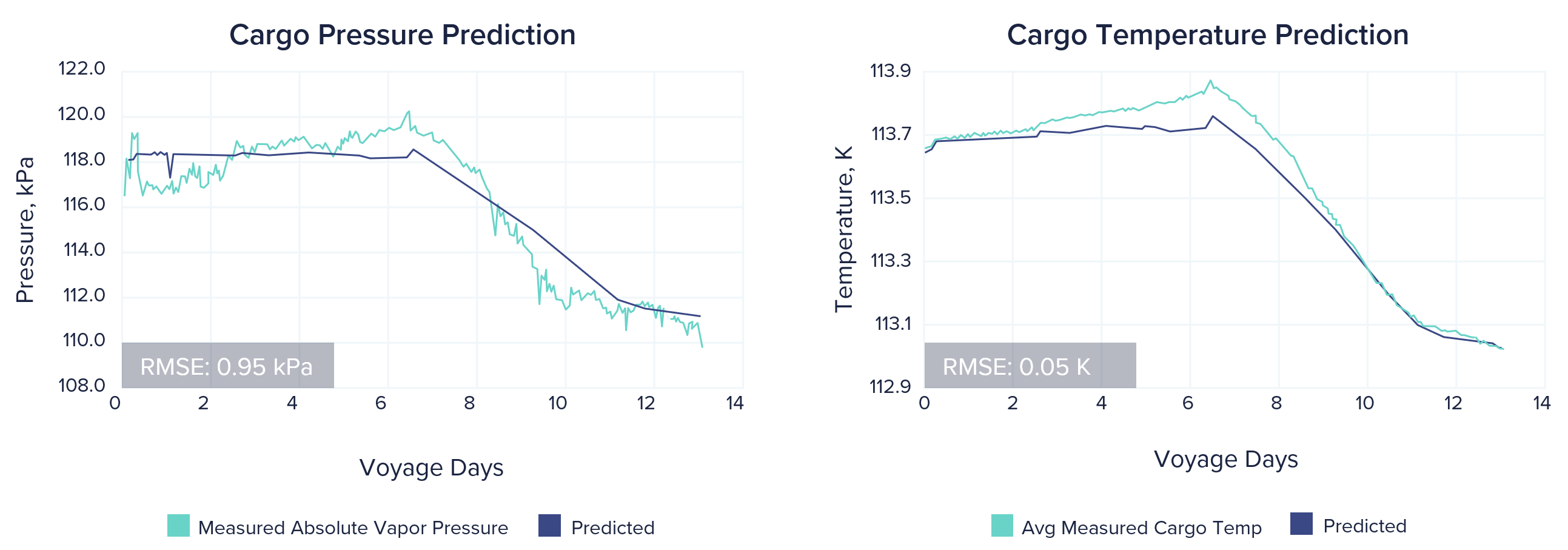

By using standard industry chemical relationships, vessel-specific empirical data, and machine learning, Nautilus develops hyper-accurate condition models to simulate the impact of operational decisions and setpoints.

Leverage hyper-accurate condition models to simulate the impact of operational decisions and setpoints enhancing efficiency and crew empowerment.

Reliquefaction

System

Predicts maximum reliquefaction rate at any given time over the course of the voyage.

Cargo

Pressure

Predicts vapor header pressure as a function of cargo temperature.

Gas & Cargo Temperature

Predicts temperature as a function of the cargo tanks’ net outflow profile. Includes reliquefaction, GCU, and productive consumption.

Cargo

Composition

Predicts liquid/vapor phase composition changes over time as a function of temperature.

Flexible Data-driven Modeling Approach

Maching Learning modeling approaches enables flexible prediction, independent of exact vessel configuration. Nautlus has experience working with virtually every currently deployed combination of reliquefaction systems, propulsion systems, and tank type.

Detailed general arrangements are not required, as our data-driven approach removes the need for explicit first-principles modeling of tank geometry and systemns.

Insights

Experience BOG Optimization and Simulations

Contact us to get a demo of BOG Optimization and Simulations and learn how it can help you improve the performance of your LNG fleet.