The only service in the industry using machine learning to develop Digital Twins of every LNG cargo

Transporting Liquified Natural Gas (LNG) is one of shipping’s most notoriously complex challenges, requiring expertise and innovative technology to optimize vessel and cargo operations. As data availability across this segment expands, the need for machine learning for further optimizing planning and operations is clear. In order to assist Owners and their Operator partners, a dynamic product is required that measures changes in the temperature, pressure, and composition of the LNG cargo throughout the voyage. The ship’s master and crew must make decisions to ensure safe transportation of the crew, vessel, and cargo while also meeting ETAs at specific pressure and temperature requirements. Throughout the voyage, there is a constant need to mitigate issues of cargo sloshing and managing boil-off gas (BOG) whether it should be used as fuel, reliquified, or burned.

LNG Market Overview

Cargo is king in this industry and we are in an environment of high commodity prices, sky high spot freight rates and limited, available tonnage. Traders are taking freight tonnage on longer periods as it is more cost effective than traditional hedging strategies. Chartering this tonnage ensures that they can physically deliver the cargo while also providing flexibility to direct cargoes towards higher value deals.

That said, this change in strategy comes with its own complexity. Throughout the past year, cargoes have been changing destinations more frequently. In parallel, floating storage days continue to increase year on year due to congestion and/or increasing volatility in forward pricing. These market conditions prove the need for better simulation and monitoring of the cargo to determine the most optimal commercial outcome based on changing variables.

Additionally, cargo sellers are seeking to increase simulation capabilities to deal with regulatory and commercial pressures. Accurately monitoring and predicting cargo condition and system performance over the course of the voyage can allow commercial and operational teams to better understand how to maximize cargo delivery and profitability. The highly volatile market necessitates actionable tools that adapt to variable market conditions and match traders’ goals. The most effective way to meet these goals is through machine learning and Digital Cargo Twin modeling.

What are Digital Twins and Digital Cargo Twins?

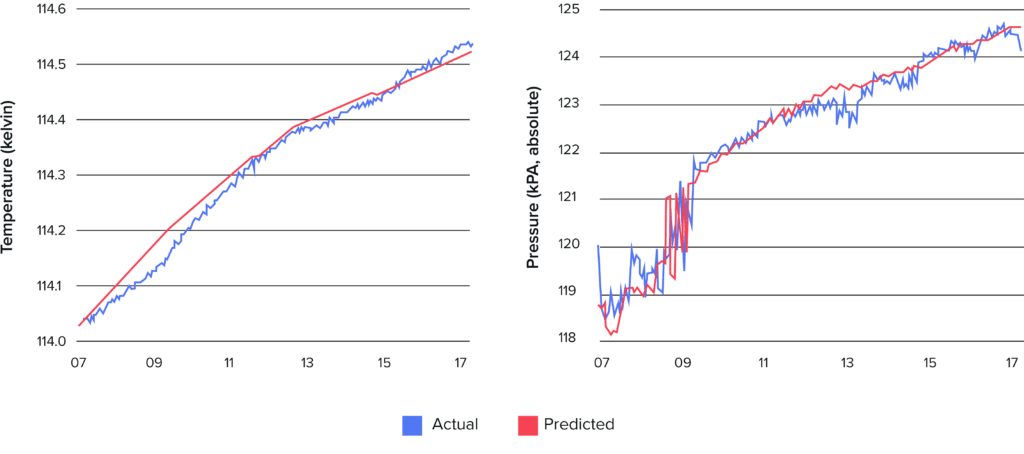

By combining thermodynamic models, weather, ship performance characteristics, real-time empirical data, and commercial requirements with proprietary machine learning models, Nautilus is able to build Digital Twins for both the vessel and for each individual cargo she carries (“Digital Cargo Twins”). These Digital Cargo Twins predict with high accuracy a vessel’s performance in forecasted weather and sea conditions, how much BOG will be generated by the end of the voyage, how temperature and pressure will evolve, as well as how that specific cargo will age or weather over the course of the voyage. Recently we have seen our Digital Twins and Digital Cargo Twins be accurate within <2% in predicting total BOG as well as temperature and pressure developments. The graphs below are an accuracy assessment of our simulation of temperature and pressure change across a 17-day voyage.

Continuous model prediction assessment: Nautilus continuously predicts cargo pressure and temperature based on real-time consumption and reliquefaction

Our clients leverage our Digital Cargo Twins as an added service on top of their existing voyage planning and management systems (which do not have sophisticated LNG models), allowing for data-driven choices when updating their voyages plans or making complex commercial and operational decisions. With our Digital Cargo twins, we are able to partner with our clients in maximizing cargo delivery, reducing AER changes, and drive collaboration between Owners and Charterers.

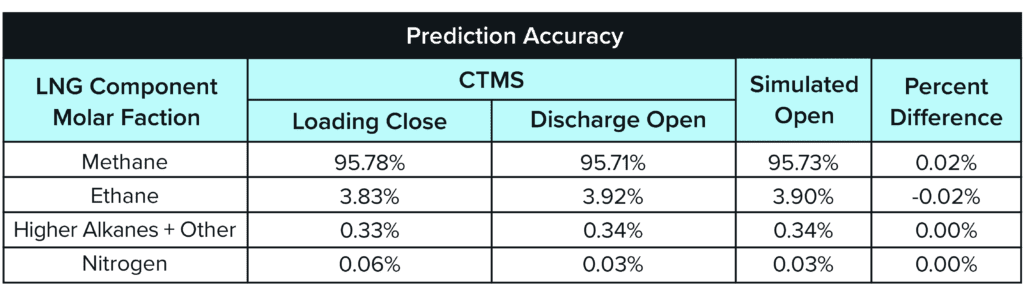

These Digital Cargo Twins also allow our customers an ability to simulate how each individual cargo will evolve from the Custody Transfer Measurement System’s (CTMS) closure to opening, taking into account cargo composition, the total expected BOG, and the impacts of weather and sloshing. Simulating these outcomes has different types of values for different operators, although arguably the most interesting today is the ability to assess claims exposure due to high-nitrogen cargos.

Cargo composition simulation results compared to CTMS open results for a two-week LNGC laden leg

Digital Cargo Twins are connected to Voyage Systems

Nautilus is currently working to make these Digital Cargo Twins available via API so they can be leveraged across our clients’ commercial & operational ecosystems. Commercial stakeholders such as Traders and Charterers may utilize the API to produce more accurate and informed cost estimates of the voyage, while enabling portfolio shipping teams to identify the best vessel for the trade. Access to dynamic performance data also empowers teams to forecast voyage metrics far more efficiently compared to the majority of internal voyage calculation tools currently available.

Digital Twins and Digital Cargo Twins inform Boil-off Gas Optimizations

Using the Digital Twins and Digital Cargo Twins, Nautilus also produces Boil-off Gas Optimization in the form of dynamic recommendations on shaft speed or shaft power, paired with a recommendation on the optimal mix of gas to reliquefy and to burn off, all taking into account any operational constraints that the crew must adhere to. The operating recommendations are updated and refreshed daily with the most up-to-date data. If you are interested to learn more, check out our BOG Optimization Case Study with TotalEnergies and BW LNG.